Clinical case studies

AO4 thimble bridge

Case description

After a long history of dental work Jennifer decided to have her failing restorations and dentition replaced with and all on four screw retained bridge.

Knowing that The Implant Centre specialise in this type of cases a suitable treatment plan was agreed on, scans and impressions taken so planning between the implant surgeon, dental technician and restorer could take place to facilitate the best outcome for the patient.

Patient arrival

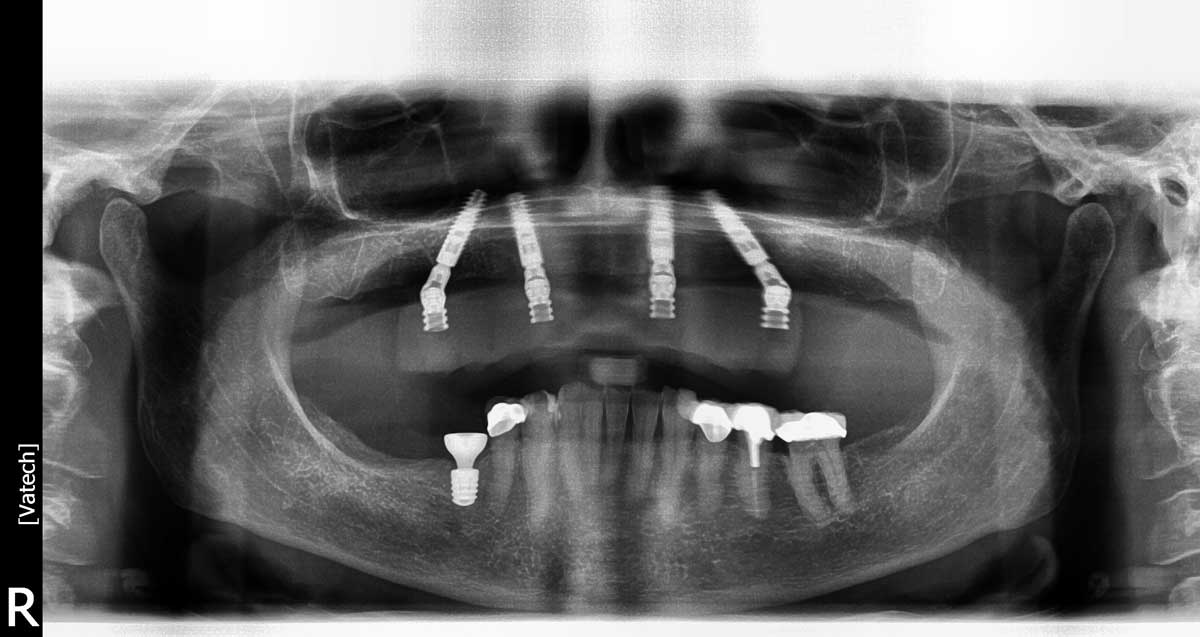

On surgery day the lab had ready a drill guide, a pre-fabricated Ivocap upper denture, positioning keys and OVD indicators. The immediate load Ivocap denture was made on an adjusted duplicate model after discussions with the implant surgeon about planned bone removal.

Due to the nature of this particular treatment the patient chose to have sedation for the upper arch clearance and implant placement. Even with the best planning surgery can be complex and things don’t always go exactly to plan.

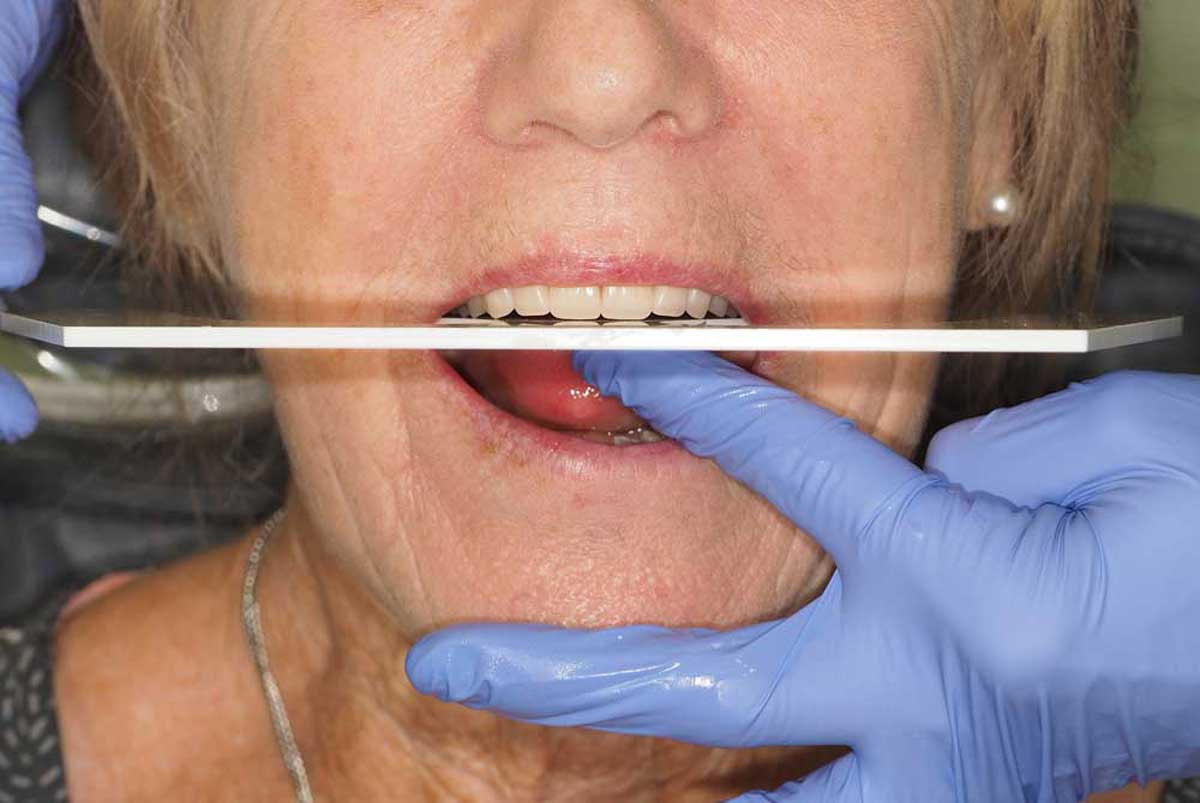

The immediate load bridge is too far forward with too much tooth show. This case, in our opinion, was boarder line and some patients would request a new temporary bridge at week one review. Jennifer was content with her bridge during the integration and healing phase though knowing that there would be an opportunity to have her preferences taken into account and future try-ins.

Process

After healing a first stage try in is made on the original immediate load cast along with an impression bar and special trays ready for the next appointment. At this appointment impressions are taken, the try-in bridge fitted so that the patient can give the technician feedback about the temporary bridge, the try in bridge etc. so that their expectations can be hopefully met.

The new impressions are cast with soft tissue masks to help CDL ensure a totally accurate fit to the abutment replicas and provide the correct tissue pressure with the new bridge. A stone verification jig is also made on this model and any fine tuning of the bridge try-in. Ready for cast and detailed bridge verification.

Normally a hybrid AO4 (manufactured by the prosthetic department) is the preferred treatment plan but with Jennifer’s deep over bite and scissoring excursions we planned to provide her with a cobalt chrome bar with individual full contour zirconia crowns and custom composite gingival wrap. In the past that kind of framework would have to be “waxed up” and cast but today’s digital technology allows us to provide computer design restorations of extraordinary accuracy and strength.

Computer-aided design and manufacturing (CAD/CAM) became one of the most popular choices of fabrication for implant dentistry. CAD/CAM allows the construction of implant frameworks from various materials. The precision fit of fixed implant frameworks fabricated by CAD/CAM exceeds the fit of the 1-piece cast frameworks.

The case was sent to Atlantis for scanning and first stage bar design before being inspected, amendments made by a CDL senior tech. after any alterations a second QC is required before the bar is approve for manufacture and core files released. The crown designs are morphed into the original prosthetic envelope paying particular care in the aesthetic zone and occlusion to ensure that the try-in stage is duplicated exactly and ensuring the patient gets what they expect. This case was design and manufactured trough a strong collaboration between crown and bridge and prosthetic departments. Up to the scanning stage the whole preparations where in hands of a senior prosthetic technician.

Once the framework is back and the crowns are milled and sintered (in the crown and bridge department) we have another try-in where the tech can take final tooth shades and character along with custom gum colouring.

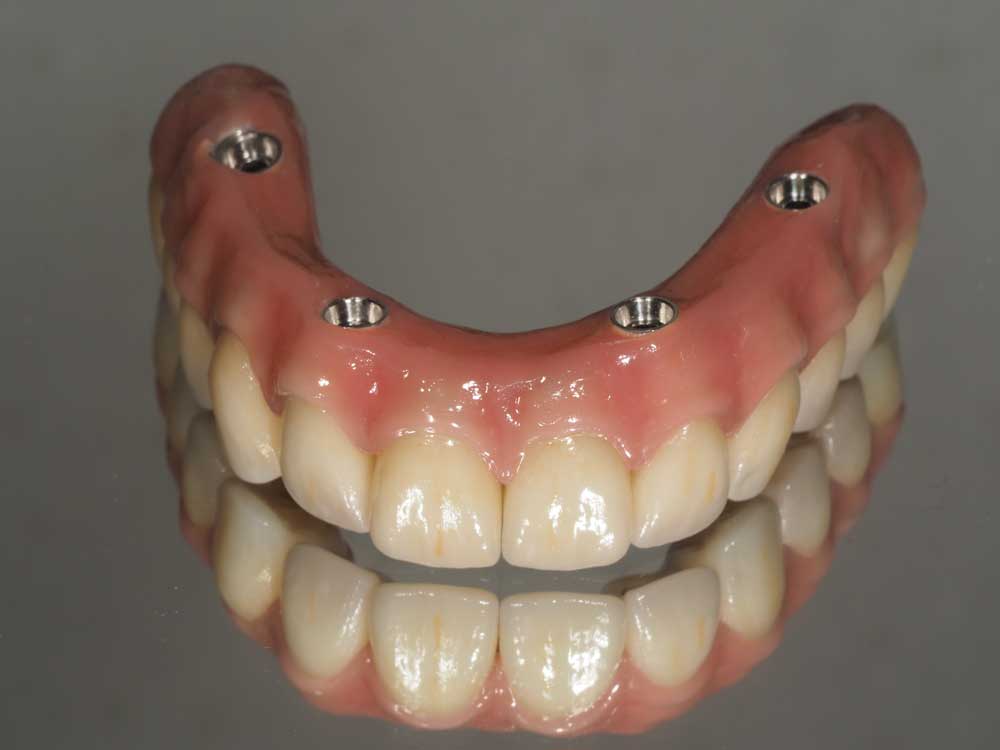

At this stage the case returned to the prosthetic technician. The “pink aesthetics” recently became a prominent subject when it comes to restoring full arches. It’s all about making false teeth look nothing like false teeth by framing them with a stunning life like gum work. In the process technician incorporates multiple shades of composite paste to create natural-looking results. The correct shade of the gum is decided with as much care as tooth shade and brings the finish restoration to high level of aesthetic outcome.

The final bridge lab side showing vital and well characterised crowns and gingiva.

Definitive bridge in the mouth with no adjustments and a passive fit onto the soft tissue and abutments giving the patient a natural smile and profile.

Verification jig

Horizontal alignment

CrCo frame try in with zirconia crowns

Tooth show patient request

Custom gum shading

Composite wrap on glazed crowns

Definitive bridge in place

FINAL RESULT

One year review showing very healthy tissue and clean fit surface of bridge both of which are outcomes of good planning, design, multi department communication and collaboration, informed patient and good materials.

Healthy tissue 1yr

Easy to clean fit surface

Let's work together